Forestry tools

Fiskars was founded as an ironworks and has therefore traditionally been involved in steel manufacturing. Fiskars is also known for its fine craftsmanship, such as scissors, knives, cutlery, etc. Agriculture and forestry have constituted another significant business area. Fiskars was self-sufficient for a long time, with an extensive agricultural department. Fiskars has also manufactured consumer products related to agriculture, with the plow being the most famous.

The forest, which was a vital source of fuel for ironworks for several hundred years, has also always been an important part of Fiskars’ operations. During economically challenging times, for example, valuable timber from the company’s forests could be sold.

Over its over 350-year history, Fiskars has expanded its operations by acquiring both competitors in the industry and companies with completely different business activities. One of the more significant acquisitions was undoubtedly Billnäs Bruk AB., which became a subsidiary of Fiskars in 1920. Billnäs was known for its various tools, and the acquisition of the company expanded Fiskars’ product range. In 1959, the company was merged as part of the Fiskars Group. Billnäs AB also manufactured forest tools. Billnäs’ most successful forest tool is the axe. The famous Billnäs axe was long manufactured with the Billnäs stamp, despite the company belonging to Fiskars.

In addition to the axe, Fiskars has also manufactured crowbars, lifting axes and hooks, bark irons, clearing knives, chainsaw chains, and various planting hoes.

Fiskars has also manufactured forestry tractors and timber cranes. A short-term collaboration with Volvo was initiated for the service and assembly of tractors. Timber cranes were first made in Porvoo and later in Salo between 1965 and 1988. The tractors were developed in collaboration with Fiskars’ own forestry department and external forestry specialists.

The Axe

The traditional felling and clearing axe consist of a blade and wooden handle. The back of the blade, i.e., the heel, can be used as a hammer or mallet. The handle is designed to be replaced as needed. This was necessary, especially for professional use. It happened that one would accidentally strike with the handle instead of the sharp blade, which could cause the handle to break. A metal piece or wire could be attached to the part closest to the blade. The handle needed to be replaceable quickly, as work time was valuable. Forestry workers could occupy themselves with making new axe handles, for example, in their spare time. The blade is attached to the handle with a wooden wedge, which needs to be tightened periodically as the blade loosens. The handle is ergonomically shaped.

There are several different kinds of axes. In practice, they are used in a similar way, i.e., for chopping and splitting, but they are all designed for specific purposes and tasks. Common axe models include the splitting axe, the carving axe, the outdoor axe, and the wedge axe. In the picture below, you can see a Fiskars-manufactured stamping axe, which was used to mark trees that were to be felled, floated, or divided.

A stamping axe from Fiskars museums collection of artifacts.

Over the years, Fiskars has manufactured many different types of axes. Originally, the axe consisted of a steel blade and a wooden handle. A significant innovation was made in the 1980s when handles began to be made of plastic. This meant that the axe was both cheaper and easier to produce. The result was an affordable but functional product for consumers.

A Fiskars-manufactured builders axe from Fiskars museums collection of artifacts.

Billhook

The billhook is used to clear branches or twigs from trees. The blade is long, flat, and sharp on one side. There are several different sizes and types of billhooks. Some can be handled with one hand, while others require two hands.

Billhooks used by the Fiskars volunteer fire brigade, and manufactured by Oy Billnäs Ab, a subsidiary of the Fiskars company. They are from Fiskars museums collection of artifacts.

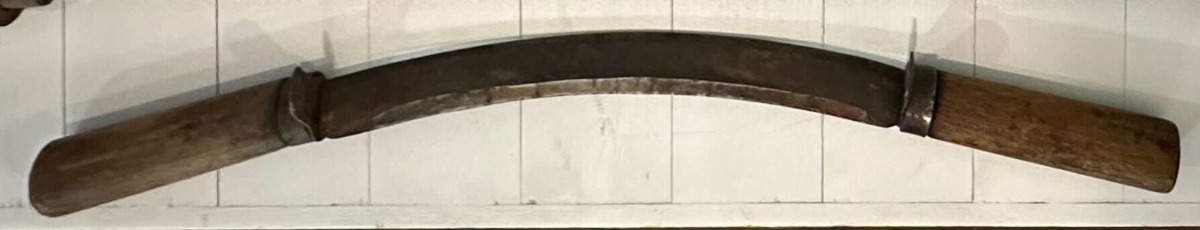

Drawknife

A drawknife is a tool used for stripping bark from wood. It resembles a long-bladed knife with handles at both ends. The blade often curves forward at the ends to ensure that the section being stripped stays within the blade area. Stripping can be done with either a pushing or pulling motion.

A drawknife from Fiskars museums collection of artifacts.

Log tongs

Log tongs are used for handling and stacking timber. The tool is practical even for long logs. The tongs cuts slightly into the tree, providing better grip when handling.

A pair of Fiskars-manufactured log tongs from Fiskars museums collection of artifacts.

Frame Saw

A frame saw consists of a saw blade and a main and middle part made of wood, and a tensioning band with wooden pins that connect the main wooden parts. The saw blade and tensioning band were usually purchased, but the saw itself was usually carved. The tensioning bands were often made of hemp, as it was a durable material. The bow saw was most commonly used between the 1920s and the 1950s, after which it was replaced by the frame saw. Later, this was also replaced by the chainsaw.

A frame saw from Fiskars museums collection of artifacts.

Crosscut saw

The crosscut saw, also known as a pit saw or timber saw, together with the axe and the bow saw, was one of the forest worker’s most important tools for a long time. In addition to the blade, the saw had two handles, as it was intended for two users.

A crosscut saw from Fiskars museums collection of artifacts.