The industrial move from the ironworks in Fiskars was not something that happened quickly or because of one specific decision. It was a series of different events, the reconstruction of Fiskars Corporation was in conjunction with the changes within the community. In the year of 1952 the narrow-gauge steam locomotive called “Pikku-Pässi” was decommissioned and this was later seen to be one of the possible reasons for the start of the Fiskars de-industrialisation. Shipping by trucks became the most effective way of transporting goods since they decommissioned the locomotive. And when the CEO of Fiskars Corporation changed in 1957 to the graduate engineer Fjalar Holmberg he wanted big changes for the Corporation and sought to modernize the company by moving the head office from Fiskars to Helsinki.

During Fjalar Holmberg’s time Fiskars also took over many other companies. Even though this provided Fiskars with new technology, the financial situation of the company declined. Holmberg bet high on developing new products but they were not a big success. The microwave is one of these items that failed to pull through in the favor of the Finns, and would need to wait until the 1980’s to become popular in Finland. The Fiskars Corporation got into a tight economical situation with a downward spiral due to the high amount of companies bought and the effort put into development work did not see the estimated success. Hence the Fiskars Corporation decided to reverse this downward spiral by replacing Fjalar Holmerg in 1966 to the temporary directors Bror Wahlroos and Ingvar Blomqvist. Göran J. Ehrnrooth stepped up as CEO after working prior as COO for half a year. Now started a full reorganization of the Fiskars Corporation and they sold all the products and industrial activity that was affecting the Corporations economy badly. Steel was one of the resources that Fjalar Holmberg also had invested in, but was not seen to be profitable any more.

The steel was removed from the primary production of Fiskars Corporation and was replaced by plastic. The wind up of the steelwork happened at Åminnefors steelworks, which was owned by Fiskars Corporations since 1890, and the steelwork moved over to the new Corporation Ovako, of which 36% was owned by Fiskars Corporation. Due to the international depression that followed the oil crisis, Fiskars Corporation had to await better times to sell unprofitable units as late as the 1980’s and thereafter they were able to concentrate on producing consumer goods. The most popular and highest selling item came to be the scissor with the orange plastic handle.

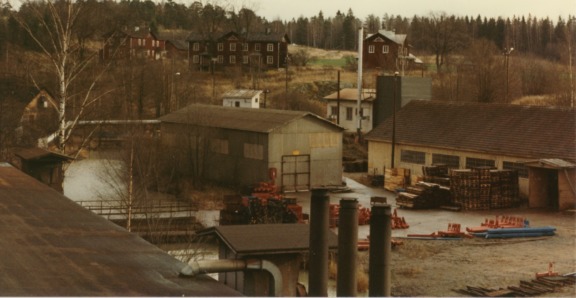

The story of the “orange scissors” had its start when Fjalar Holmberg ordered several machines that had a new and simplified grinding method. These machines were complicated and never became a success. However the personnel at the fine cutlery mill produced a new type of scissor with the plastic orange handle. It looked different from the previous models and was cheaper to produce and on top of that also more durable. Due to the fact that Fiskars back then couldn’t foresee the huge popularity this new type of scissor would bring, they had built an assembly hall of 800 m2. Almost immediately it was proven to be way too small and in 1972 a bigger production facility was built in the outskirts of Billnäs ironworks, an ironwork that has been in the ownership of Fiskars Corporation since 1920. When Fiskars Corporation took over Billnäs ironworks, Fiskars also took over the production of tools, which was marketed under the Billnäs trademark.

The primary reason for de-industrialization of Fiskars ironworks wasn’t the steelchrisis during the 1970’s like it was in other regions. Instead it was the location that was unsuitable for modern industrial function that caused the production activities to move away. There were plans on building new facilities on the outskirts of Fiskars ironworks, in the Gesterby fields, but these plans were quickly canceled since Pojo municipality was not prepared to build the municipal engineering required for such a new project. Instead the modern production facilities were built in Billnäs.

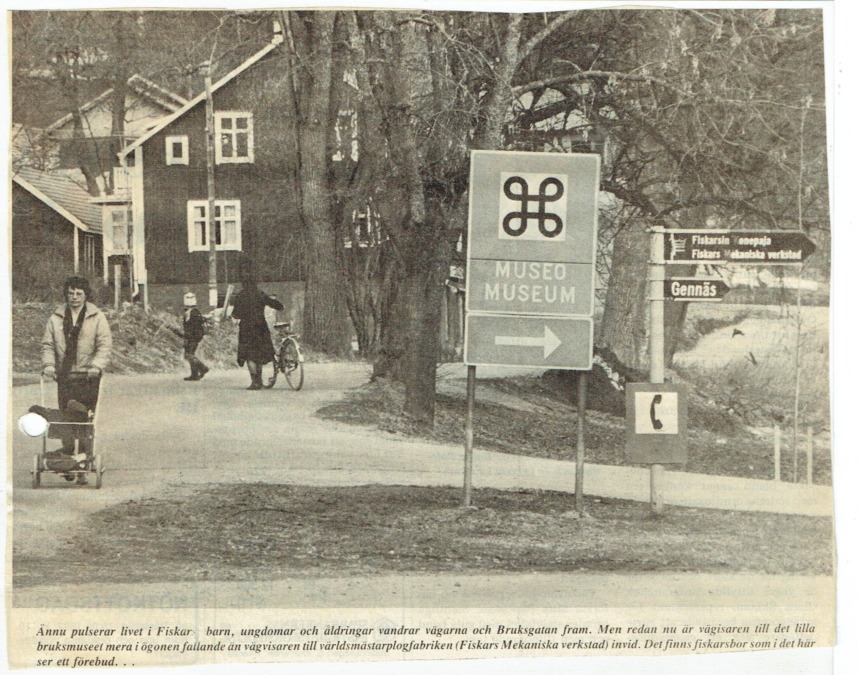

Thanks to the reorganization made during the 1960’s and 1970’s, which helped Fiskars Corporation to get through the steelchrisis, very few workers lost their jobs. However when the production facilities moved away from Fiskars, the people moved with them. Fiskars went through a large depopulation, and in the end there lived mostly elderly people left. And the houses lacked amenities according to the normal house standards of the 1980’s.

The industrial production slowly declined and the last factory left was the knife factory. This was located in the building that originally was built for making traktor plows, and in 2001 the knife factory also moved to Billnäs. Fiskars had received permission from the Finnish Heritage Agency to build a new modern factory in the culturally and historically valuable Fiskars ironworks on the one condition that the production facilities would stay in Fiskars. To build the new modern factory an old beautiful residential house Fagerbo had to be demolished. Ten years later production of plows ended due to economic loss. After the plows they produced knives, hence the name of the building changed and has since stayed as the Knife Factory.